Welcome to

Home Appliance Diy

Hotpoint Indesit motorsUNPLUG FROM MAINS. |

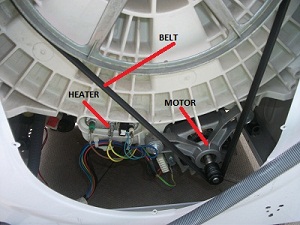

Remove the belt,unplug the wires and unscrew the two bolts,then pull the motor it should slot forward ( it may need a bit of a tap ) and can now be removed from the machine. |

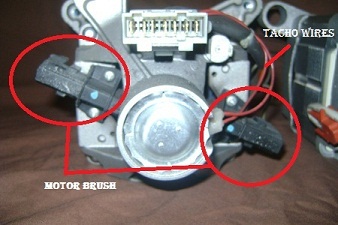

The majority of problems are down to worn brushes.The brushes are located on the rear of the motor , remove the two screws the brushes can be removed and inspected.There are lots of different types so i took the old ones into the shop and got the right ones. |

The new brush is on the left and the worn brush is on the right.A worn brush can cause drum not to turn,or the machine will lock the door and do nothing, or will pump for a second then stop then pump again .I always check the brushes. |

This is an 3 phase motor.Look no brushes.Can`t do much with these.The wiring connections are listed below . |

This is another type of motor.The two red wires shown in the picture are the tacho wires,when the motor turns it sends a signal down these wires and back to the pcb. |

| Another type of motor. |

This is the Indesit motor( there are a few types of motor so i look for the tacho wires , and the armature wires go to the brushes you can determine which type it is and its not what it says on the machine).Taking 1 and 2 as the tacho wires , it`s easy to , determine the rest.The pins are numbered 1 to 7.The reading, when measured with a multimeter,is also listed. Pins 1 - 2 Tacho wires.Pins 3 - 5 Full field. Pins 6 - 7 Armature. Pin 4 Is the tapped field. |

This is the Hotpoint fhp motor (there are a few types of motor so i look for the tacho wires and the armature wires go to the brushes,you can determine which type it is and its not what it says on the machine).Counting from right to left the pins are numbered 1 to 7.The reading, when measured with a multimeter,is also listed. Pin 1 - 2 Tacho.Pins 3 - 4 Field Pins 5 - 6 Armature. Pins 7 Field tap. |

| TESTING | FHP | CESET | BOSCH |

| TACHO | 135 ohms | 68.7 ohms | 200 ohms |

| CENTER TAP FIELD | 0.47 ohms | 0.41 ohms | 0.65 ohms |

| MAIN FIELD | 1.26 ohms | 1.25 ohms | 1.3 ohms |

| ARMATURE | 1.5 ohms | 1.78 ohms | 2.0 ohms |

| TESTING | READING |

| MOTOR PROTECTOR 1 - 2 | 0.0 ohms |

| WINDING 3 - 4 | 6.4 ohms |

| WINDING 3 - 5 | 6.4 ohms |

| WINDING 5 - 4 | 6.4 ohms |

| TACHO 6 - 7 | 120 ohms |

To fit the belt , place the belt around the motor and on the pulley until the belt goes tight. |

Then turn the pulley while holding the belt untill the belt stretches and slots into place.Make sure when the drum is turned , a couple of times , that the belt lines up central on the pulley. |

If you cannot find what you are looking for or need help then just drop me a message at Appdiy@yahoo.co.uk.